Advancing Power Generation with Ultra-Low Emissions: Hug Engineering's Breakthrough

The Challenge: Stricter Emission Limits in Power Generation

The power generation industry in the USA is evolving rapidly, driven by increasing energy demands and stricter environmental regulations. Data centers, industrial plants, and power providers face the challenge of maintaining high power output while meeting ultra-low NOx, CO, and VOC emission requirements. Traditional exhaust gas treatment solutions struggle to balance these competing demands, leaving operators in search of innovative, reliable alternatives.

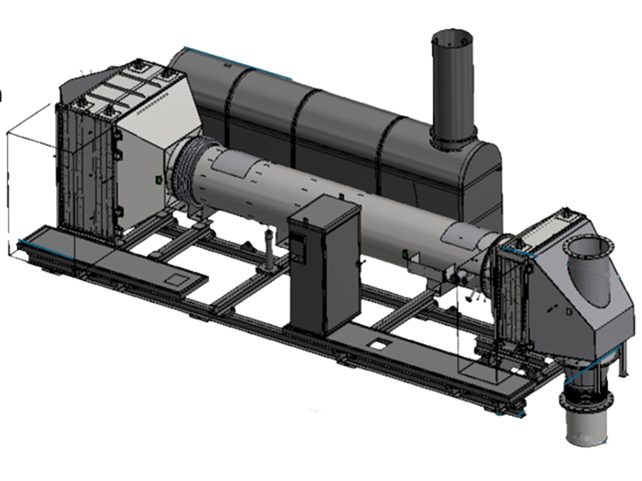

Engineering Excellence: Hug Engineering’s NG Engine Solution

At Hug Engineering, we have embraced this challenge head-on, pushing the boundaries of what’s possible in exhaust gas aftertreatment. Our natural gas (NG) engine solutions for Data Center Power Generation not only meet but exceed the toughest industry requirements.

Thanks to our cutting-edge technology, customers can install more engine power within the constraints of their existing air permits - maximizing output without breaching environmental limits. This gives data centers and power providers the freedom to scale operations and future-proof their installations while staying fully compliant.

"Achieving ultra-low emissions while maintaining operational efficiency is a complex challenge. Our team has worked relentlessly to fine-tune every aspect of our solution, ensuring that NOx, CO, and VOC emissions reach unprecedented low levels. Customers recognize that we have accomplished something truly groundbreaking."

Setting New Industry Standards

Our latest advancements in SCR (Selective Catalytic Reduction) technology have allowed us to achieve:

- NOx reduction of more than 98% - with real-world results showing emissions dropping below 1.5 ppm.

- CO reduction of over 98%, ensuring compliance with the most stringent air quality standards.

- VOC reduction exceeding 95%, minimizing environmental impact and ensuring a cleaner power generation process.

The Technology Behind Ultra-Low Emissions

The key to our success lies in two critical components: high-performance catalysts and advanced control systems that allow precise ammonia dosing. By continuously monitoring and adjusting reactant mixing, we ensure an optimal reduction process, maintaining ultra-low NOx, CO, and VOC levels with minimal ammonia slip.

This level of precision not only secures compliance - it enables operators to increase total installed engine capacity within their permitted emission limits, redefining what’s possible for modern power generation.

“Innovation is at the core of Hug Engineering. We take on the challenges that others shy away from, constantly improving our technology to help customers stay ahead of regulatory changes. Our ability to achieve below 1.5 ppm NOx emissions is a testament to our expertise and commitment to excellence.”

Industry Recognition & Market Impact

By taking on projects that others don’t dare, we continue to set new industry benchmarks. Hug Engineering has built a reputation for pioneering solutions that allow businesses to operate efficiently without compromising on environmental responsibility. Our ability to achieve emission levels that were once considered impossible has positioned us as the go-to partner for companies aiming to install more power within the same environmental footprint.

The Future of Power Generation is Here

Hug Engineering’s forward-thinking approach has redefined what’s possible in exhaust gas aftertreatment. With our proven ultra-low NOx, CO, and VOC solutions, customers can confidently rely on us to tackle even the most demanding emissions challenges.

Looking ahead, we remain committed to pushing the boundaries of innovation, helping the industry transition toward cleaner, more sustainable power generation. The results speak for themselves - We don’t just reduce emissions - we enable progress.