Mive Eco in cooperation with Hug Engineering announce the agreement with Azimut|Benetti Group for the installation of complete SCR exhaust systems produced in accordance with the new IMO Tier III regulation.

Azimut|Benetti, world leader in the production of super yachts, is the first to announce an agreement with Mive Eco for the supply of exhaust systems equipped with a Hug Engineering SCR system for the abatement of exhaust gas emissions generated by propulsion engines. Mive Eco, a company already world leader in the production of exhaust gas systems, starting this year will integrate its systems with the SCR systems of Hug Engineering, leader in its market segment and belonging to the Faurecia Group.

An agreement with the world's leading manufacturer of super yachts that is configured as a real innovation for the sector. In fact, the collaboration with two excellences such as Mive Eco and Hug Engineering will allow Azimut|Benetti to guarantee the possibility of purchasing a "low emission" version for its models over 24 meters.

----------------------------------------------------------------------------------------------------------------------------------------------

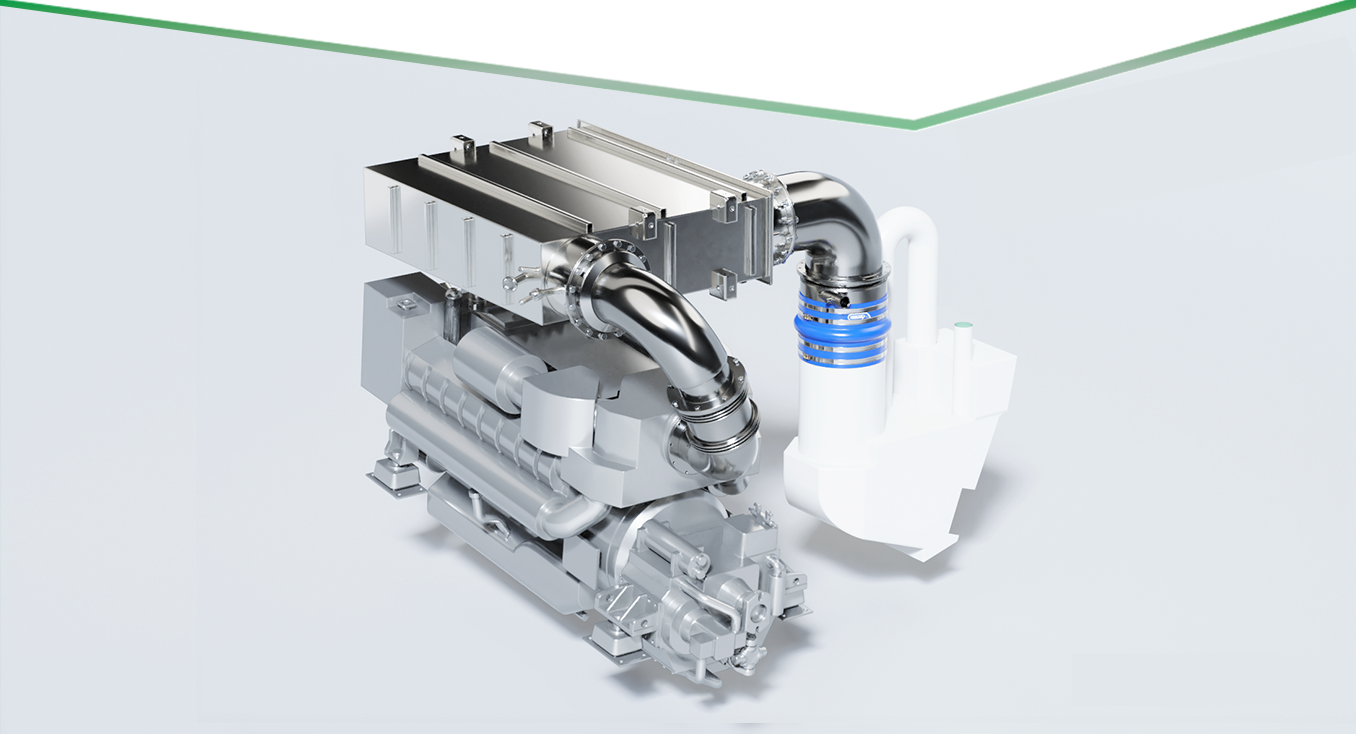

Hug Engineering has developed, tested, and certified a new version of its Selective Catalytic Reduction (SCR), able to adapt to the engine room of the Azimut|Benetti Group's displacement, semi-displacement and planning yachts, minimizing the overall dimensions

Mive Eco has integrated this latest generation SCR into its systems by offering Azimut|Benetti a complete system of all connection ducts, risers, support structures and high-performance insulation in order to guarantee perfect operation, compliance with the values of back pressure, surface temperature on the components and safety of the yacht, despite the limited space available.

The need is to meet the limit level of NOx emissions defined by IMO as "Tier III" which, starting from 2021, has extended to yachts of less than 500 gross tonnage and longer than 24 meters, and has become a mandatory requirement for sailing in ECAs (Emission Controlled Areas).

Years before the entry into force of the new emission limits Azimut|Benetti had asked its exhaust line supplier Mive Eco to integrate an "SCR" in the engine room for at least 8 yacht models, without any reduction in habitable areas or garage volume and impact on engine power.

Mive Eco had taken up the challenge by involving Hug Engineering, its long-standing partner, which has been supplying its best-in-class products to the main shipyards in the European area since 2016, when the IMO TIER III emissions standard came into force for all yachts over 500 gross tonnage.

Mive Eco has reworked its exhaust systems and simultaneously Hug Engineering has finalized the development of a completely new "CCV" catalyst (Cordierite Coated Vanadium), which, after 3 years of laboratory and bench tests, has proven to meet the performance targets in the limited space of an engine room.

The second challenge, after the catalytic one, was to identify the "system" able to adapt to the size of the engine, in less than 50cm of height, resisting high mechanical stress due to speeds above 30 kn and temperatures up to 500 ° C.

Mive Eco and Hug Engineering after months of studies have developed the first versions of exhaust gas systems integrated with compact SCR suitable for yachts over 24 meters and under 500 GT.

Once the system was in place, Hug Engineering began the certification process to obtain an IMO TIER III IMO standard compliant EAPP certificate based on the IMO Tier II engine. In this way it is possible to use SCR in the ECA area and possibly use the engine in Tier II version in areas where it is not yet easy to refuel AdBlue (Urea) on board.

The joint efforts undertaken between 2020 and 2021 by the three companies involved, Azimut|Benetti, Mive Eco and Hug Engineering, have made it possible to achieve the goal of having a viable solution both technically and commercially, which can be immediately offered to any customer interested in buying an ecological yacht, having full freedom to sail anywhere in the world and being able to count on the full value of the boat at the time of resale.

Documentatie downloaden

| Bijlage | Grootte |

|---|---|

| 2021.10.20.Press Release. Azimut Benetti Group and Mive Eco collaboration. | 197.17 KB |