Facilities

Hug Engineering possesses highly sophisticated laboratories to define the best solutions for our customers. Thanks to that, we can ensure the best quality and reliability of our products.

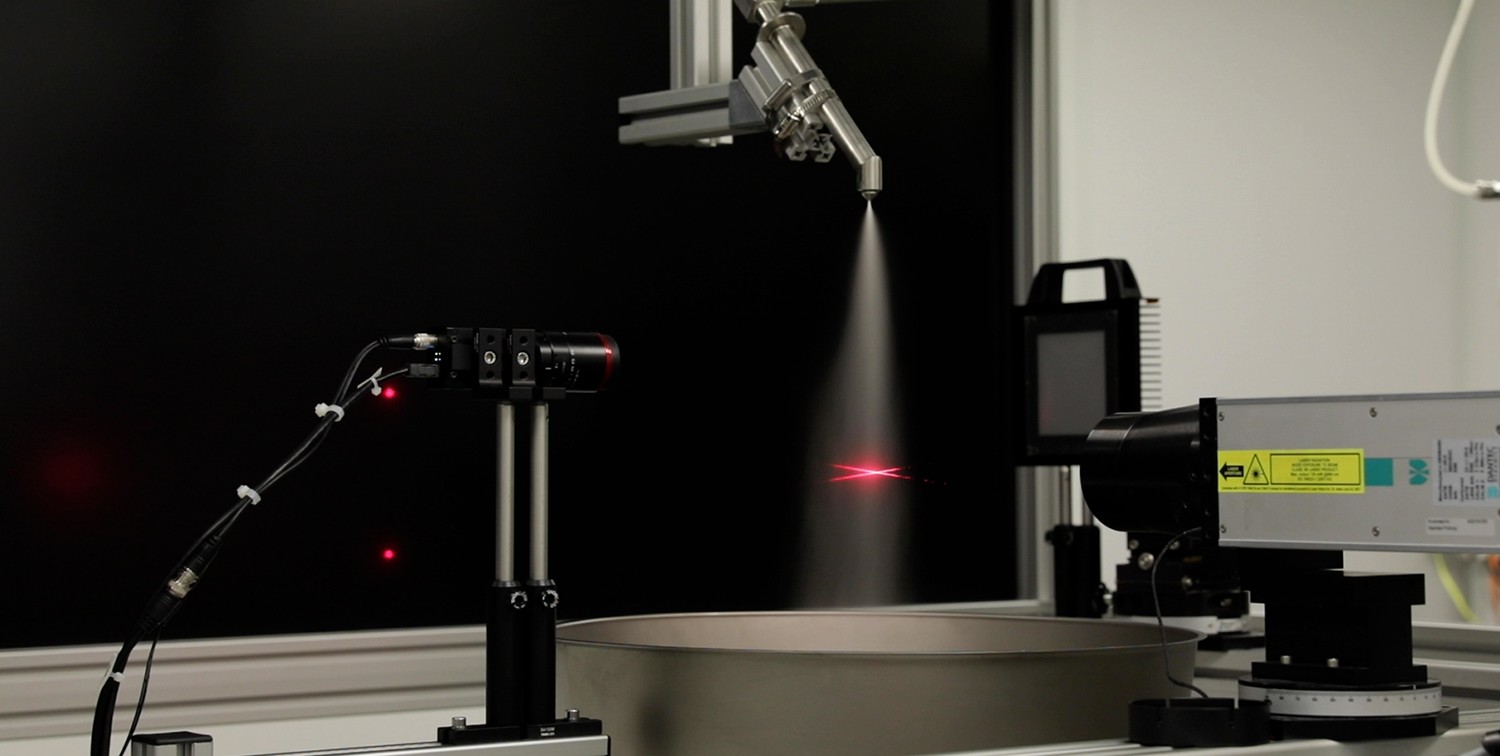

Hug Engineering recently upgraded its spray lab in order to improve the determination of the spray key characteristics (spray angle, droplet size and velocity) thanks to a Phase Doppler Anemometer. The detailed spray data is important to develop injectors and ensuring a robust dosing system design.

With our recently deployed analytic equipment and trained experts, we use the materials lab for innovation and product development. Furthermore, we are using this equipment to control quality of the production environment.

For many years, Hug engineering has been investing in developing its own system testing capabilities with state-of-the-art equipment.

Multiple synthetic exhaust test benches and engine test benches allow us to develop new products. Extensive lab testing of components ensures rapid implementation of new technology while confining operational integrity and performance.