Technology

Hug Engineering has gathered a broad scope experience by developing key components and complete exhaust systems, including in-house control systems (software development and hardware integration). Therefore, we are able to offer optimized systems to meet our customer requirements.

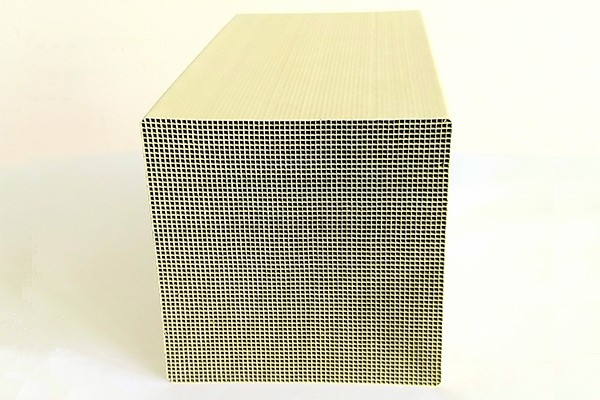

Our ceramic based Diesel Particulate Filters (DPF) are specifically designed for the high horsepower applications. This key in-house developed part is the corner stone to achieve more and more demanding emission regulations and still taking into account the high horsepower operational requirements.

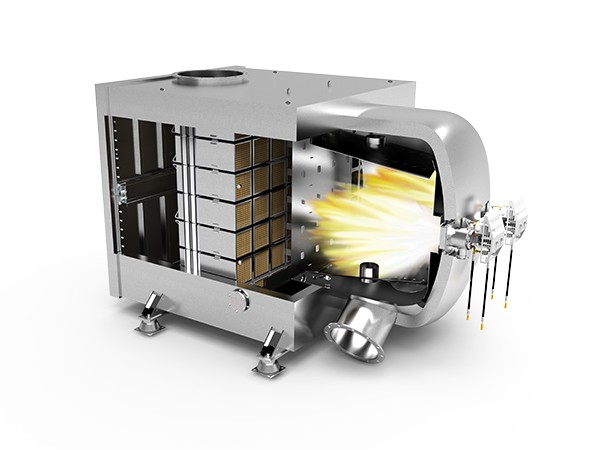

Our tailormade active regeneration systems provide you with maximum availability and full operational flexibility, no matter what application you want to clean up. The E-power system takes care of your Genset below 200kW, whereas our Nauticlean burner handle the more powerful engines up to 3MW.

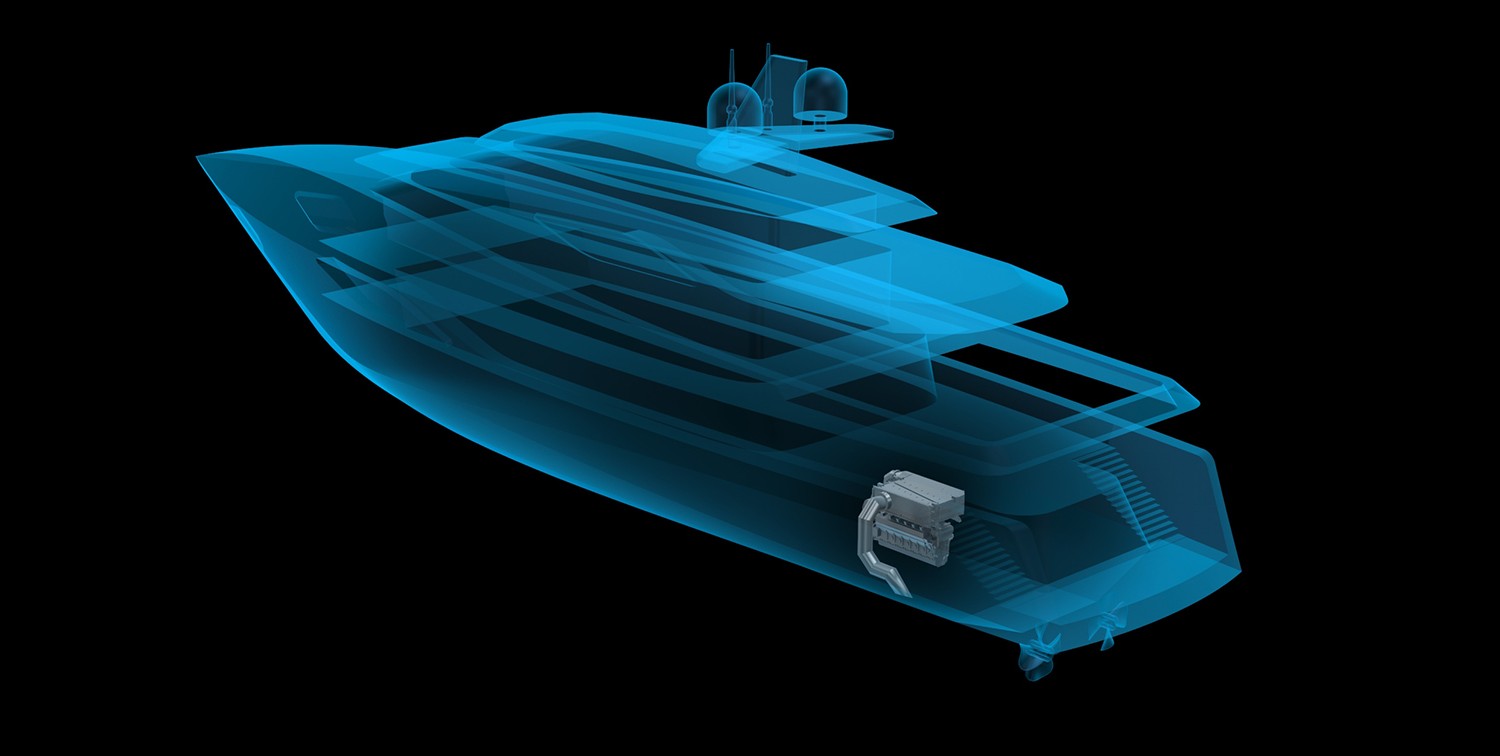

Our selective catalytic reduction catalysts (SCR) technology converts nitrogen oxides (NOx) into harmless dinitrogen (N2) and water (H2O) emissions. We continuously develop our SCR catalysts even further. The most recent one is a high-performance SCR catalyst for specific applications, such as yachts, in order to deliver a compact solution for confined spaces, that can fit any engine room.

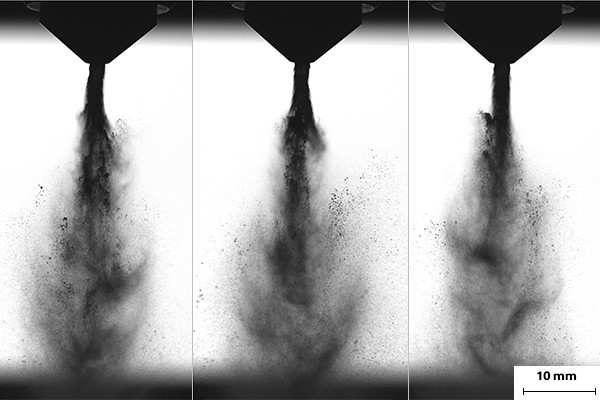

Our dosing systems are air-assisted and a key enabler to our high-performance SCR catalyst. Using in-house testing facilities and expertise, we strive to deliver optimized performance and reduced operating cost to our customers.

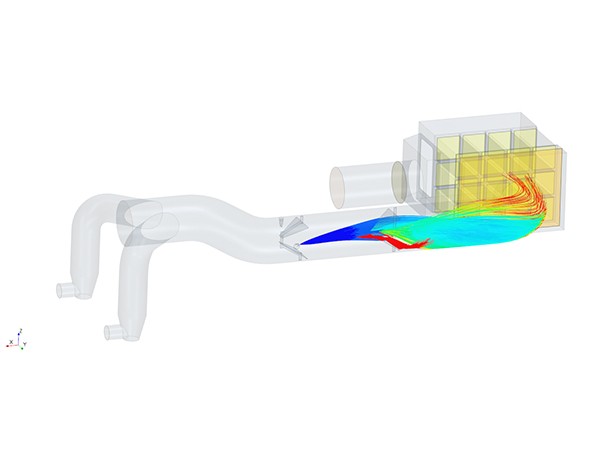

Our mixing of reactants is key to maintain the SCR system performance. Our target is to define the necessary mixing performance to reach the required uniformity index (UI) at the lowest backpressure possible, using our experience and our 3D simulation tools.