MAP Tower: The Intelligent Brain Behind Emissions Control

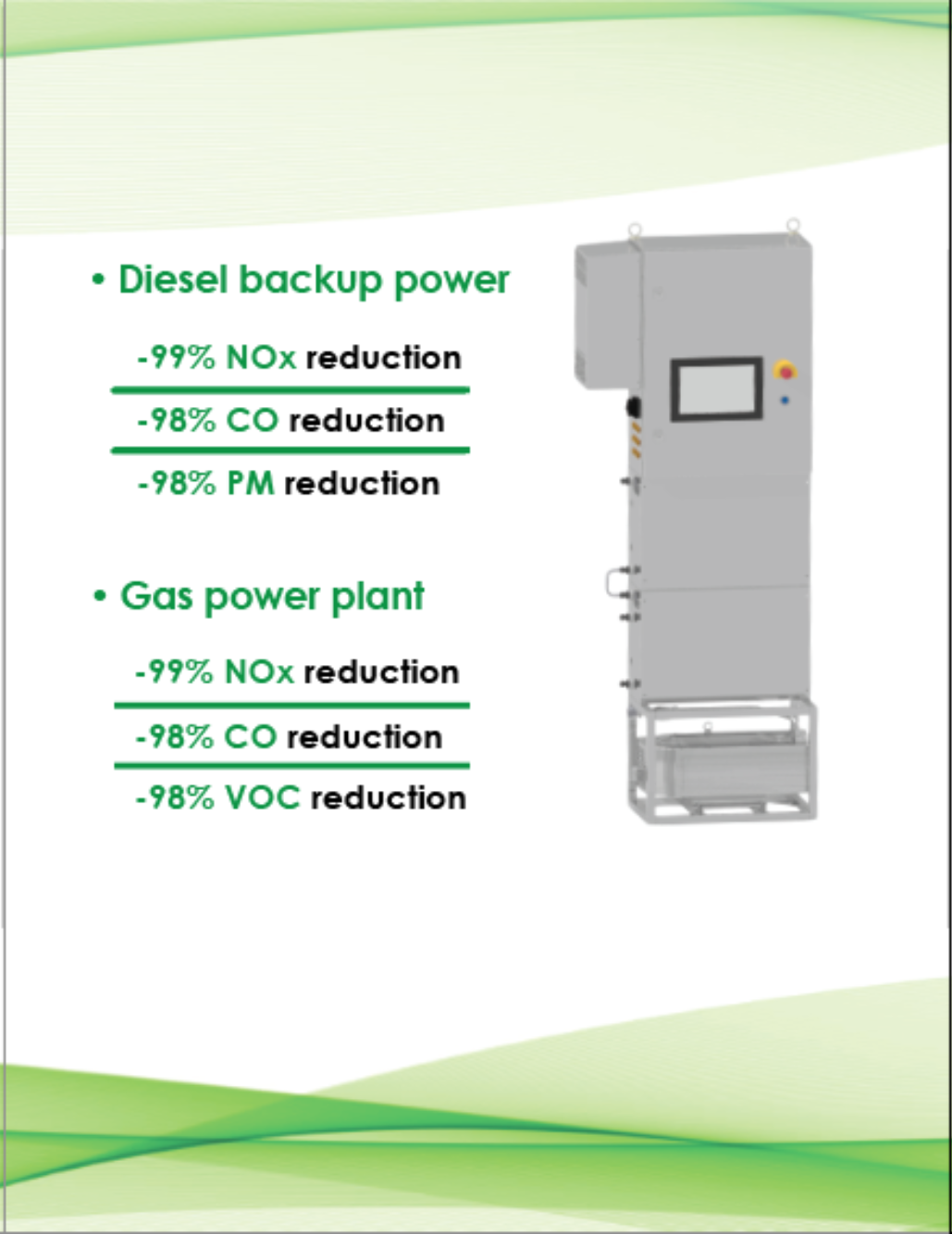

In today’s world of stricter emission regulations and growing demands for efficiency, system intelligence matters more than ever. That’s why Hug Engineering developed the MAP Tower - a smart, centralized control and monitoring system that brings together real-time data, advanced dosing control, and predictive diagnostics into one compact unit.

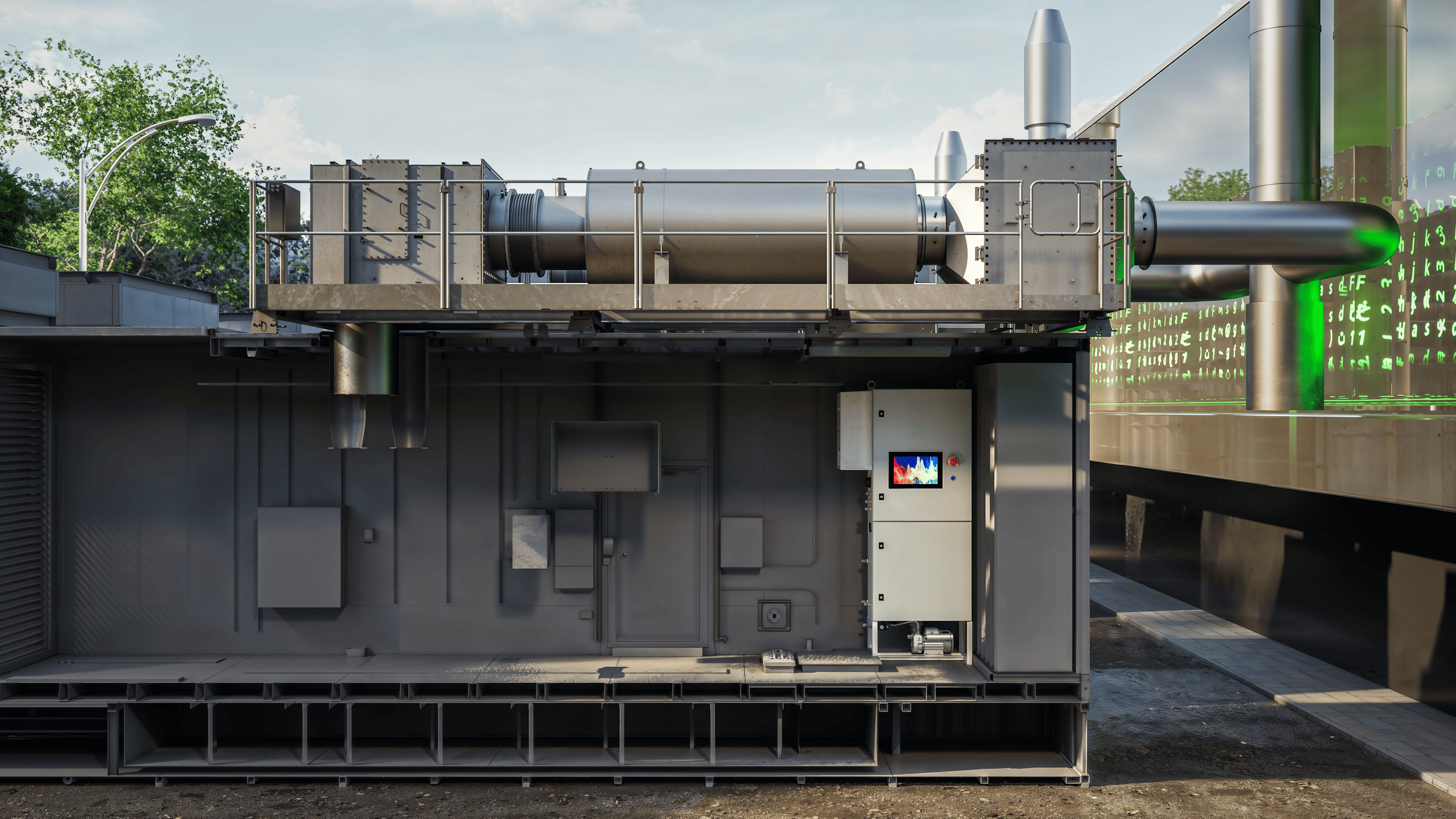

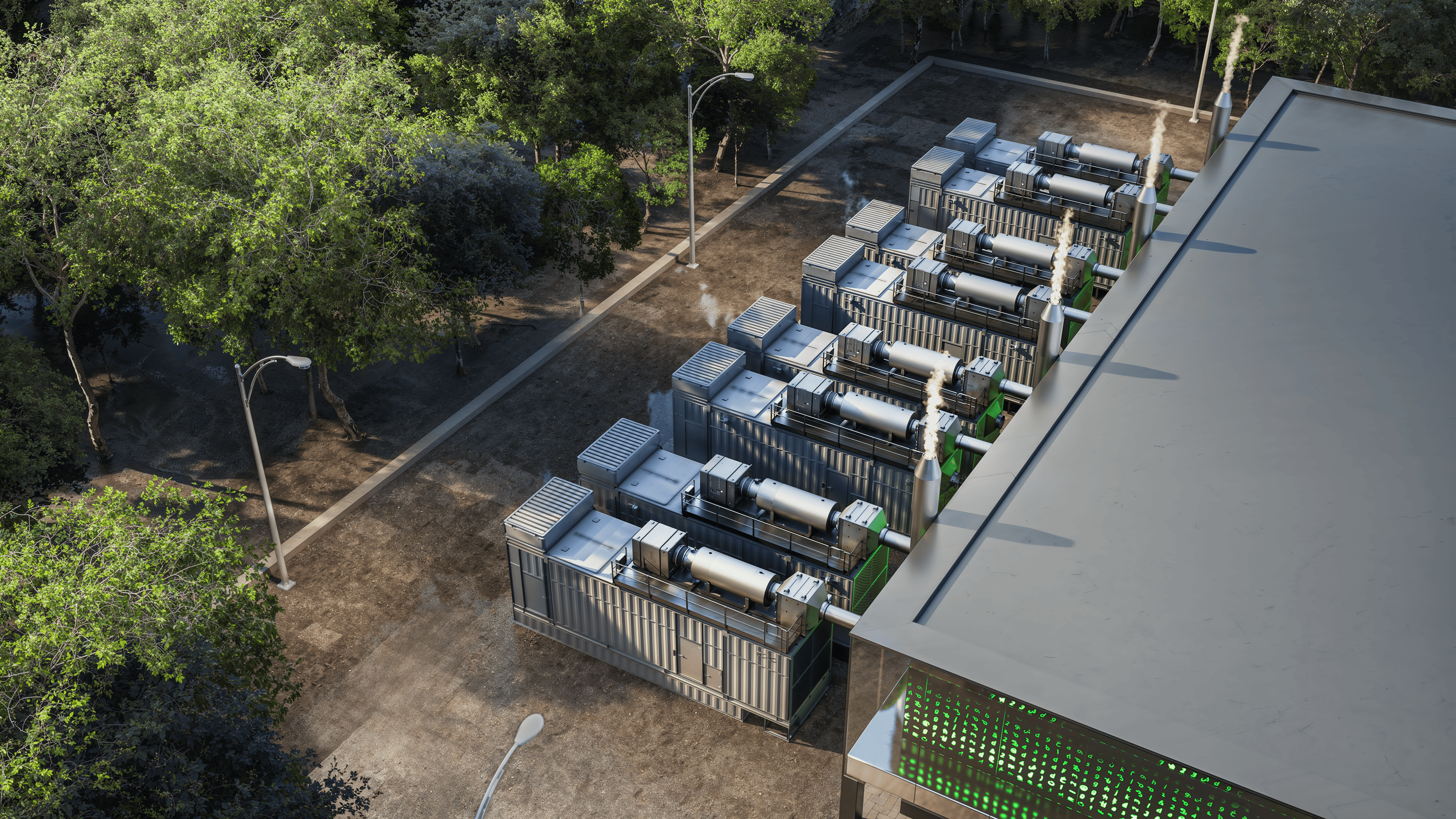

Built for high-performance aftertreatment in stationary applications - particularly data centers - the MAP Tower offers a level of integration and automation that transforms how exhaust emissions are managed.

What Is the MAP Tower?

The MAP Tower is Hug Engineering’s modular control and monitoring unit for aftertreatment systems - primarily Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) technologies.

It consolidates four essential system functions into a single, factory-assembled tower:

- control

- dosing

- reactant supply

- air supply

All components are pre-mounted, pre-cabled, and fully tested, reducing on-site installation time and ensuring reliability from day one.

It’s the brain of the system - the MAP Tower controls everything from the dosing unit to reactant and air supply, with full real-time monitoring and closed-loop logic.

Designed for Data-Critical Environments

The MAP Tower is currently focused on stationary installations, especially data centers, where uptime, footprint, and compliance are non-negotiable. It’s designed to fit into containerized environments with single-lift installation, allowing customers to simply place, connect, and go.

Customers just lift it up, lay it down, plug it in - and it works.

Solving Customers' Challenges

The MAP Tower is not just a smart controller - it’s a smart solution to common challenges:

✅ Faster Installation & Commissioning

Because everything is pre-integrated, customers only need to connect basic power and signal inputs. This eliminates weeks of on-site cabling, piping, and troubleshooting.

✅ Reduced Complexity & Human Error

Whereas traditional systems required coordinating multiple components on-site, the MAP Tower arrives ready to run, with all internal connections tested under Hug’s quality standards.

✅ Ideal for Modular Construction

Its compact, pre-wired design aligns perfectly with the containerized, modular build strategies used in modern data centers and industrial facilities.

Closed-Loop Intelligence

At the heart of the MAP Tower is a closed-loop control system that continuously monitors and adjusts emissions performance.

What It Measures:

Inlet & outlet NOx concentration

Temperature

Pressure

What It Does:

Adjusts urea dosing in real time

Compensates for clogging filters, load fluctuations, and other variable conditions

Maintains emission targets without operator input

The system takes care of itself - only when it can’t hold the limits anymore, it asks for help.

Advanced User Interface with Role-Based Access

The integrated HMI (Human-Machine Interface) ensures everyone - from operators to technicians - has the right access for their role:

Operators: View system status and data trends

Trained customers: Make basic parameter adjustments

Service technicians: Full commissioning and troubleshooting access

Alerts are clearly displayed:

Warnings allow continued operation

Alarms trigger a system stop for safety or compliance reasons

What Makes MAP Tower Different?

Many control systems claim to be smart - MAP proves it:

Uses electrochemical NOx sensors for precise feedback in closed-loop control

Helps Hug meet extremely low NOx targets (as low as 1.7 ppm) that competitors shy away from

Fully modular - customers can scale capacity or functionality by adding new modules, rather than redesigning the whole system

MAP is only one piece of Hug’s emissions mastery. Our advantage comes from integrating:

Exhaust apparatus design

Catalyst & filter layout

Injection & mixing technologies

Inside the MAP Tower

The system is neatly split into upper and lower functional zones:

Top Unit (The Brain)

PLC Controller

HMI Display

Embedded Control Logic

Lower Modules (The Body)

Dosing Unit: Converts urea pressure to precise injection

Reactant Pump

Compressor: Supports air-assisted atomization for optimized spray patterns

All main parts are pre-integrated - mounted together, tested, and shipped as one smart system.

Proven Performance: A Success Story

When our U.S. data center projects demanded exceptionally low NOx emissions, competitors declined - but Hug said yes.

Thanks to the MAP Tower’s real-time logic and dosing precision, the system met performance requirements others considered unattainable. The result? A satisfied customer, a proven solution, and a clear market edge.

While others said it couldn’t be done, we delivered ultra-low NOx with MAP and our complete system know-how.

Final Word

With the MAP Tower, Hug Engineering delivers what modern industries demand: intelligence, integration, and impact.

Whether you’re managing emissions in a hyperscale data center or pushing regulatory limits in a demanding application, the MAP Tower offers the clarity, control, and confidence you need.